SAFETY GAS MASKS

Since 1980, we have been manufacturing gas masks, based on innovative concepts and design.

With time Mestel Safety, became strongly involved in providing safety solutions all over the world.

SGE LINE

Comparison Table of Masks

| SGE 150 | SGE 400/3 | SGE 400/3 BB | |

|---|---|---|---|

| Filter ports | 1 (front) | 3 (side & front) | 3 (side &; front) |

| Face silicone seal | Silicone | Silicone | Butyl |

| Face shield coating | No | Yes | Yes |

| Additional bottom port | No | Available | Available |

| Drinking device option | No | Yes | Yes |

| Lenses support | Available as access | Available as access | Available as access |

| Integrated hood | Available | Available | Available |

| Speaking diaphragm | Available on request | Available on request | Available on request |

| Mustard gas resistance | No | Face Shield Only | Yes |

Download Mestel Safety SGE Gas Masks Manual (EN)

Download Mestel Safety SGE Gas Masks Manual (IT)

Download Mestel Safety SGE Gas Masks Manual (FR)

Download Mestel Safety SGE Gas Masks Manual (ES)

Download Mestel Safety SGE Gas Masks Manual (DE)

Download Mestel Safety SGE Gas Masks Manual (ZHG)

Download Mestel Safety SGE Gas Masks Manual (TR)

Download Mestel Safety SGE Gas Masks Manual (SL)

Download Mestel Safety SGE Gas Masks Manual (SK)

Download Mestel Safety SGE Gas Masks Manual (SE)

Download Mestel Safety SGE Gas Masks Manual (RU)

Download Mestel Safety SGE Gas Masks Manual (RO)

Download Mestel Safety SGE Gas Masks Manual (PT)

Download Mestel Safety SGE Gas Masks Manual (PL)

Download Mestel Safety SGE Gas Masks Manual (NL)

Download Mestel Safety SGE Gas Masks Manual (MT)

Download Mestel Safety SGE Gas Masks Manual (LV)

Download Mestel Safety SGE Gas Masks Manual (LT)

Download Mestel Safety SGE Gas Masks Manual (KR)

Download Mestel Safety SGE Gas Masks Manual (JP)

Download Mestel Safety SGE Gas Masks Manual (IE)

Download Mestel Safety SGE Gas Masks Manual (HU)

Download Mestel Safety SGE Gas Masks Manual (HR)

Download Mestel Safety SGE Gas Masks Manual (FI)

Download Mestel Safety SGE Gas Masks Manual (EL)

Download Mestel Safety SGE Gas Masks Manual (EE)

Download Mestel Safety SGE Gas Masks Manual (DK)

Download Mestel Safety SGE Gas Masks Manual (CZ)

Download Mestel Safety SGE Gas Masks Manual (BR)

PERFORMANCES & SPECIFICATIONS

SGE150, SGE400, SGE400/3 & SGE400/3 BB full face masks are Personal Protective Equipments (PPEs) that fall under category III in compliance with the EU Regulation 425/2016.

The masks follow the harmonized EN136: 2000 standard and satisfy the requirements laid down for class 3 (Firefighting & special use). Only screw filters are used, conforming to the European standard EN-148 part 1.

FOGGING UP OF VISOR

(Tested up to –30° C.)

– Starting cold: no fogging up

– Starting warm: no fogging up

LIGHT TRANSMITTANCE MORE THAN 90%

FIELD OF VISION

– Total 87%

– Overlapping 80%

COMMUNICATION

Microphone, earphones and hearing protection devices can be easily fitted to the mask. Due to the position and type of speech membrane, loud speaker use is easy and efficient.

APPLICATIONS

The masks can be used in conditions requiring protection for both eyes and the respiratory apparates. It is particularly recommended for industrial, military and agricultural sectors where the air is contaminated by toxic and/or hazardous substances.

HEAT RESISTANCE

Masks are flame resistant and heat-radiation resistant.

The mask does not melt or catch fire when tested accordingly with the EN 136 standard.

PROTECTION AGAINST CONVENTIONAL WEAPONS

The visor protects not only the eyes, but the whole face against fragments, stones, splinters caused by explosions. It can stand with no damage (break or perforation) to the impact of a steel sphere 6.35 mm caliber bullet hitting the mask at any point at the speed of more than 150 m/sec.

Blast effects do not impair the protection performances as all the membranes are able to stand significant pressure. The speech diaphragm in particular is the open type and does not use the old rigid metal membrane.

FOGGING UP OF VISOR

(Tested up to –30° C.)

– Starting cold: no fogging up

– Starting warm: no fogging up

LIGHT TRANSMITTANCE MORE THAN 90%

FIELD OF VISION

– Total 87%

– Overlapping 80%

COMMUNICATION

Microphone, earphones and hearing protection devices can be easily fitted to the mask. Due to the position and type of speech membrane, loud speaker use is easy and efficient.

APPLICATIONS

The masks can be used in conditions requiring protection for both eyes and the respiratory apparates. It is particularly recommended for industrial, military and agricultural sectors where the air is contaminated by toxic and/or hazardous substances.

HEAT RESISTANCE

Masks are flame resistant and heat-radiation resistant.

The mask does not melt or catch fire when tested accordingly with the EN 136 standard.

PROTECTION AGAINST CONVENTIONAL WEAPONS

The visor protects not only the eyes, but the whole face against fragments, stones, splinters caused by explosions. It can stand with no damage (break or perforation) to the impact of a steel sphere 6.35 mm caliber bullet hitting the mask at any point at the speed of more than 150 m/sec.

Blast effects do not impair the protection performances as all the membranes are able to stand significant pressure. The speech diaphragm in particular is the open type and does not use the old rigid metal membrane.

Technical information

VISOR

General features

The transparent visor is the actual supporting body of the SGE protective masks. Its task is to replace the rubber bodies previously employed by traditional designs to bear the weight to which the mask is subjected. The visor supports the head harness, valves, filters, regulators, etc.

The main part consists of a large round surface in front of the eyes, and it set back in the structure, thus keeping the overall dimensions to a minimum, reducing the risk of scratching and allowing the use of optical instruments. The material used is a specially coated polycarbonate (excepting SGE150), which transmits more than 90% of UV-visible light.

Key performances

Laboratory tests have show that the polycarbonate body is left unharmed by a 6.35 caliber bullet hitting it at a speed of more than 150 m/seconds. This means that the the visor supplies the same protection than a protective helmet.

The coating treatment of both sides of the visor in SGE 400/3 and 400/3 BB makes the polycarbonate resistant to aggressive substances. Samples of the treated material have been subjected to mustard gas penetration tests. After over 50 hours, mustard gas failed to penetrate through the tested specimens.

Any visor may be decontaminated several times without any deterioration, using all the normal decontamination methods including immersion in boiling water.

Materials

Visor: Transparent polycarbonate

Coating treatment (SGE 400/3; SGE 400/3 BB only): Polysiloxane resin

Main adavantages

• a substantially reduced mask weight

• a better field of vision

• protection of the face is guaranteed by the impact and cut resistant structure

• the mask fits comfortably even when the wearing time increases

• the wearer can be easily identified due to the total transparency of the face-piece, helping to normalize conditions and maintain discipline

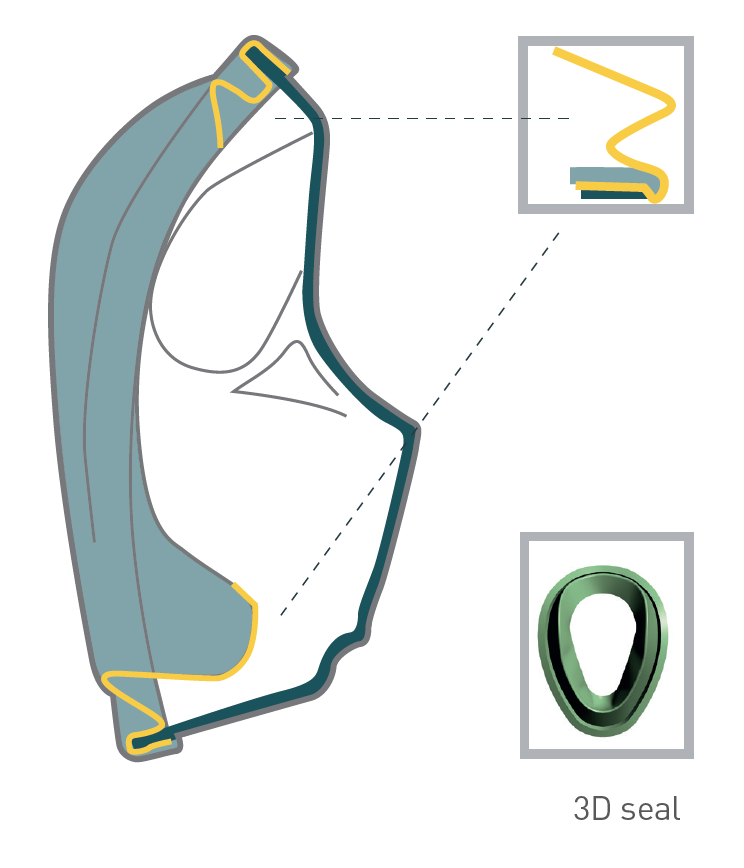

FACE SEAL

General features

Due to the use of an integral load-bearing facepiece, it was possible to make the rubber faceseal much lighter, as its only function is to act as a seal.

Traditional masks consist basically of a load-bearing rubber structure fitted with two sealed eye-pieces, and since the rubber body has to bear the weight of all the accessories attached to the mask it has to be made rigid and thick (heavy and uncomfortable) and will therefore not adhere comfortably to the wearer’s face.

Our face-seal, on the other hand, is made by soft rubber with a supple bellows type structure which allows a perfect sealing and a very high degree of comfort even after a prolonged use. The bellows type structure also allows the comfortable fitting to all face shapes.

As a whole, straps, face-seal and stiff body of the mask together provide far more comfort than traditional masks.

Materials

Silicone and butyl rubber (only 400/3BB)

Face seals assembled on SGE150 and SGE400/3 are made by silicone. This hypoallergenic material allows a perfect comfort during wearing the mask together with optimal mechanical performances and tear resistance.

The SGE400/3 BB face seal is made by butyl rubber in order to improve the protection to toxic gases thanks to the low permeability of this material.

FILTER FITTINGS

General features

The SGE masks have a threaded fitting for application of standard filters (DIN 3183, UNI EN 148-1). The fitting is contained in a single unit which also comprises the exhalation valve.

The shape of the internal ring nut allows perfect ventilation of the whole face-piece, preventing misting even at low temperatures, thanks to thE mask design, antifog is not necessary.

Mechanical characteristics

The material used is black polyarilamide, created for aeronautical and aerospace requirements.

In addition to very high impact resistance, it is not affected by aging or atmospheric factors.

Its abrasion resistance is such that after testing with over 3000 assembly/disassembly operations, the filter had sustained no wear.

MEMBRANES

General features

The exhalation membrane is fitted onto the same unit containing the filter fitting.

Externally the membrane has a structure which, although it covers the whole membrane, still allows easy discharging of the exhaled air.

The purpose of this covering structure is to keep a sufficient volume of uncontaminated air in continuous contact with the membrane.

Mechanical characteristics

The exhalation membrane has been made to require minimum effort even at very high flow rates.

The excellent memory of the membranes has been achieved by a combination of good design and high grade material.

A considerable increase in resistance to chemical agents, has been achieved, using as constituting material a butyl based compound instead of the traditional natural rubber.

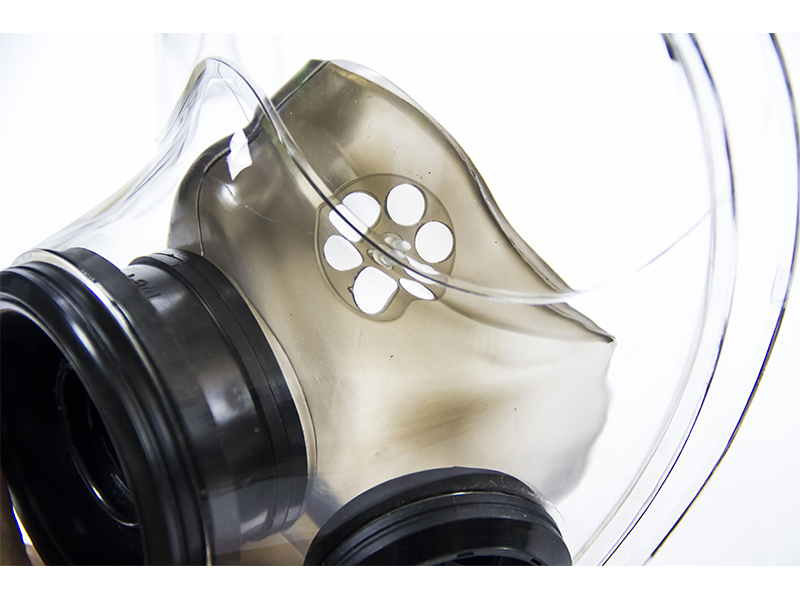

NOSE CUP / ORINASAL POCKET

General features

The design of this component is critical to the effectiveness and comfort of the mask. Because it comes in direct contact with particularly sensitive areas of the face, the correct choice of shape and material was vital. The nose-cup is made of soft silicone rubber, designed specifically for use in contact with the human body for indefinite periods of time without causing irritation or allergic reactions of any kind. The shape is designed to provide optimum comfort and efficiency; the U shaped peripheral lip performs the following important functions:

• it adheres softly and evenly to the face, following its contours perfectly

• it has a sufficiently rigid structure to ensure effective sealing during inhalation

• it is sufficiently soft to open and swell under the slight pressure caused by exhalation, isolating the nose and mouth area perfectly from the rest of the mask

Breathing valve system

Two very light inhalation membranes made by silicone are attached laterally to the nose-cup, the lower part of which is connected to the auxiliary drainage valve. The front part of the oral-nasal unit is attached into the exhalation/speech/feeding valve unit. This union is obtained by using the rubber’s elasticity, guaranteeing perfect sealing.

FRAME AND STRAP

General features

The fixing rim has the role of connecting the straps to the frame of the mask and at the same time fixing and locking the face-seal and the incorporated hood, if used. Once the rim is tightened in place by means of the special screw, it fits into a special seat in the frame of the mask.

In this way, the pull exerted on the fixing points of the head harness is transferred and distributed evenly around the whole circumference of the mask, allowing perfect adjustment of its tightness for maximum comfort and optimum sealing on the face of the wearer.

It should be pointed out that this is not possible with the traditional mask, as the pull exerted by the strap itself is secured, thus requiring the wearer to over-tighten the mask, drastically reducing the level of comfort.

SGE’s stiff body allows the straps to evenly distribute the effort around the edges of the mask, so that it is not necessary to tighten them.

Materials

Frame: Polyamide

Head-strap: NBR rubber excessively.

CLEANING & DECONTAMINATION

The mask design makes both decontamination and cleaning easier. Particular care of any contaminants deposited on the mask should be taken, performing all cleaning treatments in safe areas.

Masks can be disinfected using non aggressive disinfectants or by immersing it briefly in boiling water.

No abrasive substances to clean the Visor can be used.

If disinfection is required, a solution of diluted chlorhexidine digluconate (5%) can be used as well.

After cleaning,The mask should be left to dry in a cool, dark storage, or with a clean, soft cloth or cool air blower.